Dragon has done a very nice job with their turrets. All the current turrets

benefit from updates and refinements. The various Dragon kits provide

enough different turrets to allow you to build any example that is necessary.

The new early low bustle 75mm turret, Fig. 1, is supplied in the M4A1

Direct Vision kit without the smoke mortar port and with the smoke mortar

port in a number of other kits. Appliqué armor and the early M34A1 mount

are included in the Normandy kit, Fig. 2.

The PTO Composite M4 kit supplies both the low bustle, Figs. 3, 4, and

the high bustle turrets, Figs. 5, 6. Both turrets have cast cheek armor,

oval loaders hatch, and pistol port. Unfortunately, in the original issue of this kit, Dragon neglected

to include the lower turret half for the high bustle turret so you will

need to write to Dragon

Care to obtain the piece. The instructions for

the turrets in the PTO kit are sorely lacking and it is necessary to have

additional information if you want to assemble them correctly. For the

most part, the instructions indicate the assembly of the high bustle turret,

but they call out to use the same lower turret half for both turrets.

I suspect that if Dragon had not cut the lower turret half off the second

“B” sprue, the part would be numbered (B31) which would be similar to the

same piece supplied with the 105 turret, Fig. 12, since the sprue layouts

are identical. I have modified some Normandy instructions which hopefully

do a better job of showing how to assemble the low bustle turret, here.

Despite the fact that the instructions have “blued-out” most of the first

“B” sprue, the “B” numbers in my revised instructions refer to the first

“B” sprue.

The low bustle turret with cast cheek armor that is supplied with the

Dragon PTO kit, Figs. 3, 4, was relatively rare. The turret can be easily

modified to a more common version without the loaders hatch and pistol

port, Fig. 7.

Each turret is supplied with the appropriate mount, Figs. 8 – 11.

Fig. 12 shows the mount for the 105mm howitzer.

There are some assembly steps that can be applied to all the turrets.

Generally, I like to: 1) assemble the upper and lower halves together;

2) fill the seams 3) make any modifications such as fill the smoke mortar

port or the pistol port; 4) re-texture the smoothed out areas (using this

technique) and add back the mold parting line; 5) attach the lift rings;

6) prime the cast areas with a lacquer primer for texture; 7) add the rest

of the components and details.

My technique for creating a lip around the smoke mortar port is to

use a piece of styrene sprue that I machine and cement into the opening.

I cut the piece leaving a slight raised lip that I finish off with a bevel,

Fig. 13.

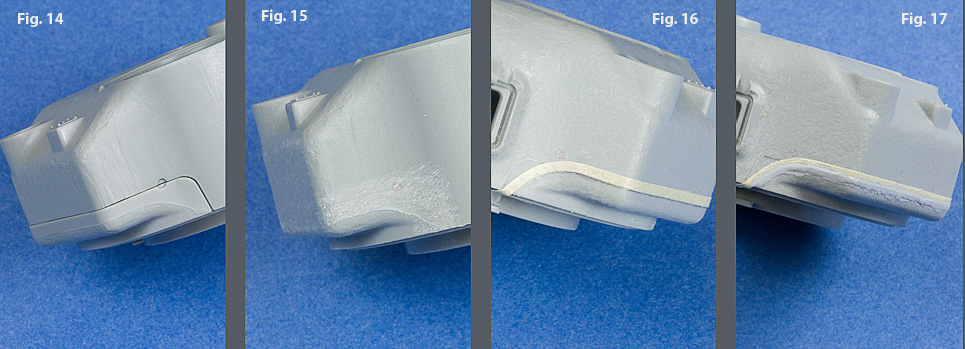

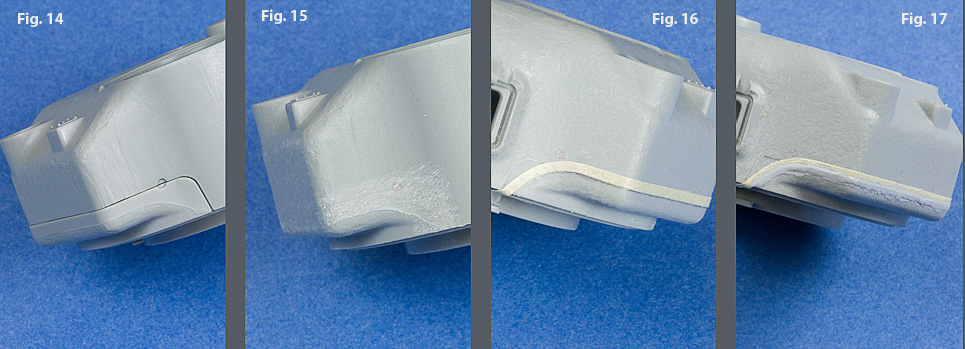

The fit between the upper and lower halves of the 75mm turrets is not

that good, Fig. 14. Dragon makes an attempt to incorporate the mold parting

line in the lower half, but because of the poor fit between the two halves,

the area needs to be filled and reshaped, Fig. 15. I then re-texture the

area using the technique described here.

I use a thin piece of masking tape to lay out the cast parting line, Fig

16. Several coats of Mr. Surfacer 500 are brushed against the tape, Fig

17.

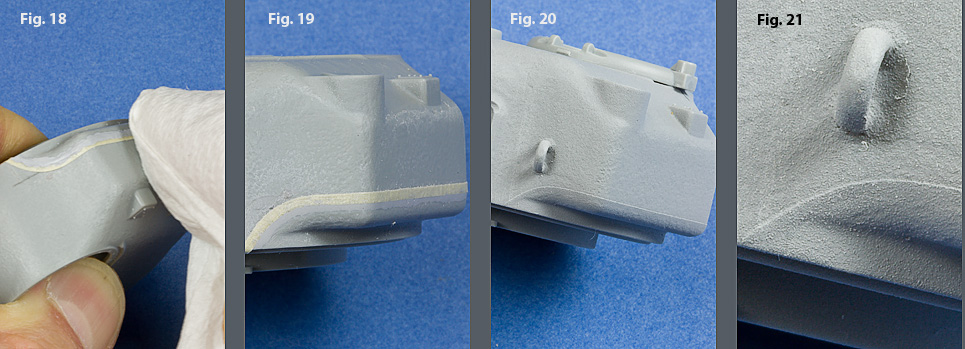

After allowing the Mr. Surfacer to dry for about an hour, I use a paper

towel moistened with 90% isopropyl alcohol to blend the Mr. Surfacer and

level it with the tape, Fig 18. Rub the towel perpendicular to the tape

rather than parallel. The result is shown in Fig. 19. After the tape

was removed, the portions of the turret that do not have cast texture are

masked off and then the turret is sprayed with a lacquer primer, Fig. 23.

The final coat should go on relatively dry. After the primer is dry, I

knock down a bit of the texture with a scuff pad. The finished line is

shown in Fig. 20. The texture of the lacquer primer can be seen in Fig.

21.

It is best to look to your reference material for placement and angle

of the lift rings. I use a variety of methods to locate the position

of the lift rings so that they are vertical and equal in height, Fig. 22.

This is the lacquer primer that I like, Fig. 23.

I have my own sequence for assembling the 75mm mount. When cementing

piece B20 into the turret, check to insure that it is parallel to the turret

face, Fig. 24. Look at the space indicated in red. This is critical because

it provides the support and positioning of the mount.

Dragon produces two versions of the M34A1 mount. Check your references

and make sure your using the correct mount. The two versions are shown

in Fig. 25. The later version (on the right) does not have the bolts on

the side and uses a slightly wider mantlet. Dragon depicts the wider mantlet

with a heavier cast texture which can be easily distinguished when compared

to the smaller version. In any case, make sure you use the correct mount

and mantlet combination.

I like to cement the mount into place first, Fig. 26. The barrel is nicely

molded but needs to be sanded smooth to eliminate the seam. Then the mounting

piece is cemented to the end of the barrel, Fig 27.

I then cement the barrel to place using a simple paper guide and a block,

Fig 28. This gives me a pretty good idea that I am perpendicular to the

backside of the turret bustle.

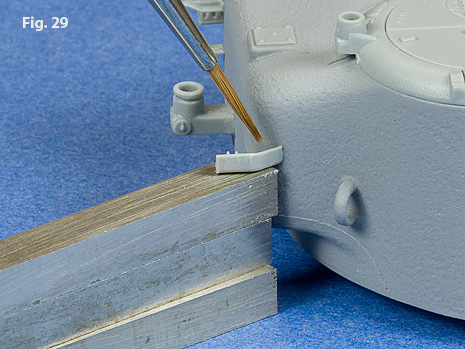

I use a simple spacer arrangment to cement on the .50 caliber barrel stowage

brackets, Fig 29. These just happen to be lathe tool bits, but you can

use what ever you have that works. This insures that both brackets are

the same height and are straight.

I cut my own periscope lids from .020” x .080” styrene strip, Fig. 30.

I find it is faster to cut them and bevel them than it is to clean up the

molded ones included in the kit. I think they come out squarer as well.

Dragon also provides very nice renderings of the both 76mm turrets, Figs.

31, 32.

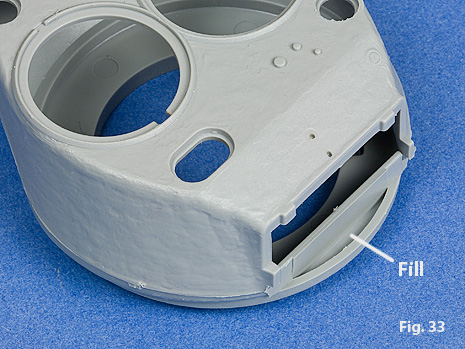

Both 76mm turrets have an open space under the mount that needs to be

filled, Fig. 33. I cemented a piece of .015” sheet over the space, Fig.

34.

The hinge pin of the hatch on the direct vision cupola is poorly represented,

Fig. 35. It should be removed and replaced with a piece of styrene rod,

Fig. 36.

Keeping in mind that all kits have issues, and certainly the Dragon kits have their share, I think they look very nice when assembled, especially the Normandy and Composite PTO. I feel that the details are very crisp and sharp. With the exception of the final drive housing and transmission issues, I think Dragon does a good job rendering the shapes correctly.

I hope this article has been helpful. I’ve enjoyed sharing some of what I’ve learned in building these kits.